What Is an Analog Input Module?

In the world of industrial automation, process control, and measurement systems, an analog input module plays a crucial role in bridging the gap between physical world signals and digital control systems. Whether you're working in a factory, a power plant, or any facility that involves automation and monitoring, understanding the function of an analog input module is essential for building effective and efficient systems. But what exactly is an analog input module, and why is it so important?

What is an Analog Input Module?

An analog input module is a hardware component used to interface analog sensors and devices with a digital control system (such as a PLC, distributed control system (DCS), or a computer-based system). It converts the continuous analog signals into digital data that can be processed, analyzed, and acted upon by the control system.

The key function of an analog input module is to convert the voltage or current signal received from an analog device (like a temperature sensor, pressure transducer, or flow meter) into a format that the digital system can understand. This typically involves signal conditioning (to scale or filter the input) and Analog-to-Digital Conversion (ADC) (to convert the analog signal into a digital value).

For example, Foxboro FBM205 is an advanced analog input module widely used in process control systems. It is specifically designed to interface with a variety of field devices and sensors in industries such as oil and gas, petrochemicals, and power generation. The Foxboro FBM205 module provides high accuracy and reliability, converting analog signals (e.g., temperature, pressure, and flow) to digital data for efficient system monitoring and control.

How Does an Analog Input Module Work?

An analog input module performs several key functions to ensure that the analog signals from sensors can be interpreted correctly by the control system:

1. Signal Conditioning

- The analog input module often has signal conditioning circuitry to adjust the incoming analog signal to a level that is suitable for measurement or conversion. This can include amplification, filtering (to remove noise), or protection (such as isolation from high voltage).

2. Analog-to-Digital Conversion (ADC)

- Analog signals are continuous and need to be converted into digital form before they can be processed by digital controllers like PLCs. The module uses an Analog-to-Digital Converter (ADC) to sample the incoming signal at a specific rate and convert it into a binary number (a digital value).

- Resolution of ADC: The resolution of the ADC (e.g., 8-bit, 12-bit, 16-bit) determines how accurately the input signal can be represented in digital form. A higher bit depth means more precise readings.

3. Data Transmission

- Once the signal is converted, the analog input module sends the digital data to the PLC, DCS, or other control systems for processing. The digital data can then be used to trigger specific actions, adjustments, or alarms, depending on the system's programming and requirements.

Applications of Analog Input Modules

Analog input modules are widely used in industries where monitoring and control of physical processes are required. Some common applications include:

1. Industrial Automation

- In manufacturing environments, analog input modules are used to monitor sensors that track variables like temperature, pressure, flow rate, and humidity to ensure optimal operation of machinery and processes.

2. Energy and Utilities

- In power plants or electrical distribution systems, analog input modules interface with sensors that measure parameters such as voltage, current, power consumption, and temperature to monitor system health and detect faults.

3. Environmental Monitoring

- Analog input modules are also used in environmental monitoring systems that measure variables like air quality, water level, and soil moisture for agricultural or environmental research purposes.

4. Automotive and Aerospace

- In the automotive and aerospace industries, these modules are used to gather data from sensors that monitor engine temperature, fuel pressure, and other vital performance metrics.

In all of these cases, systems like the Foxboro FBM205 provide reliable and accurate data acquisition, ensuring that control systems respond to real-time environmental changes and maintain efficient operation.

An analog input module is an essential component of modern automation systems, enabling the interface between real-world analog signals and digital control systems. It allows for the precise monitoring and control of industrial processes, energy systems, and a wide range of applications. By converting analog signals into digital data, these modules provide the foundation for automation and intelligent decision-making in industries around the world.

Since its inception, Xiamen WPS has adhered to the belief of taking customer needs as the core and price and quality as the lifeline, shining like a rising star in the field of industrial automation. The trust and support of customers are like warm sunshine, illuminating our development path. Our business network is like a precision gear, tightly meshing every link of industrial automation to ensure a seamless and high-quality experience for customers. Find detailed product information on our website at https://www.wps-plc.com/. Should you have any inquiries, don't hesitate to contact us at jesse@wps-plc.com.

- What Are Siemens Modules and Why Do Engineers Rely on Them?

- Why Are ABB Modules Redefining Industrial Reliability and Future Automation?

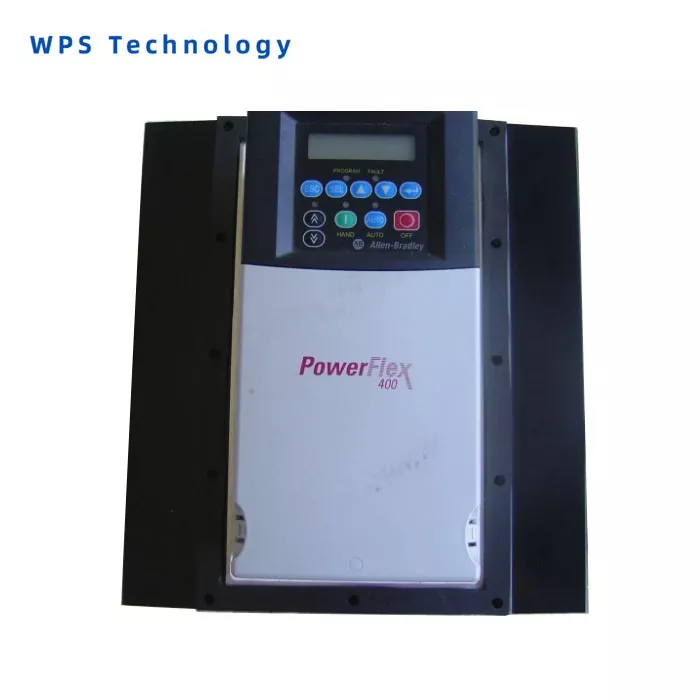

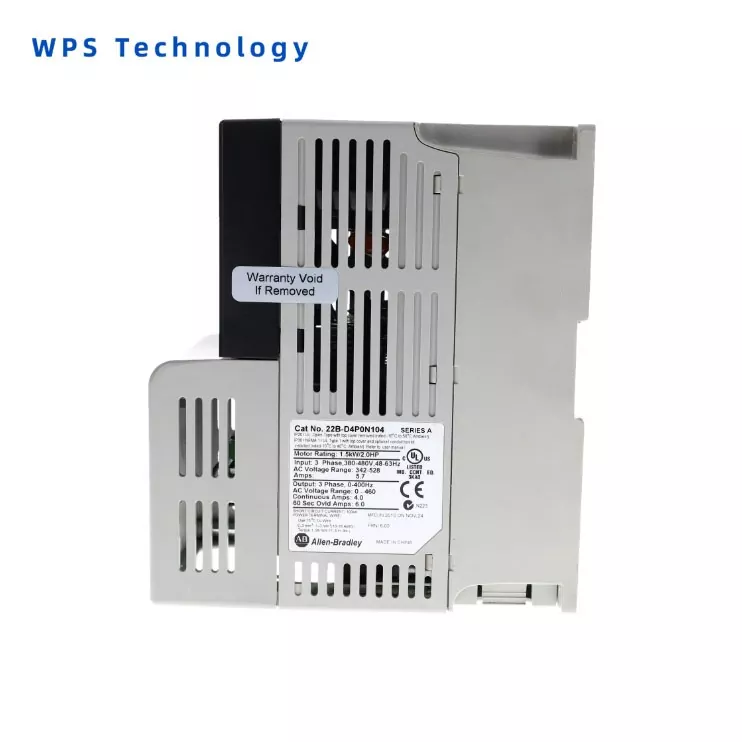

- What Makes Allen Bradley Modules the Reliable Choice for Industrial Automation?

- Why Are Schneider Modules Essential for Modern Industrial Applications?

- Why Are Siemens Modules the Smart Choice for Modern Automation Systems?

- Honeywell Modules Comprehensive Analysis: The Key Core of Intelligent Control